Bhuleshwar, Mumbai, Maharashtra

- GST NO. : 27AACPJ1600P1ZT

View Mobile Number

Copper Products

Leading Manufacturers, Exporters and Wholesaler of Copper Bars, Copper Rods, Copper Anode, Flexible Copper Products, Copper Pipes & Tubes, Copper Foils, Phosphorised Copper Balls, Copper Tapes, Lead Sheathed Copper Tape, Copper Section and Profile, Copper Strips and Braided Copper Strips from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Copper |

| Application | Medical, Automotive Industries, Power Distribution, Telecommunication,Bus Bars, Transformer Connectors, Power Transmission Equipment, Control Panels |

| Thickness | 1mm To 60mm |

| Width | 5mm To 350mm |

| Edge Type | Radius Corner Edge, Square Edge, Full Radius Edge |

| Edge Length | Up To 6400mm (21`) |

| Standard Overall Cutting Tolerance | 100mm |

Thickness 1mm To 60mm Standard IS Brand Name Jans Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jams Copper |

| Country of Origin | India |

| Feature | Excellent Quality, High Strength |

| Type | Copper Rods |

| Material | Copper, Sulphur |

| Packaging Type | Box |

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Copper |

| Shape | Oval, Ball |

| Application | Electroplating Applications, Rotogravure, Electroforming, Decorative Printed Circuitry, Electrical Ground Rod, Electro-forming, Other Functional Plating Applications |

| Size | Oval - 80mm X 30mm, Ball Minuscule 25mm, Minuscule 38mm, Minuscule 50mm Or As Per Customer Requirement |

| Standard | ASTM B265, Grade 5, Grade 9 |

| Feature | Phosphorus Content, Cleanliness |

| Weight | Per Foot |

Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Product Description:Phosphorous Copper Anode (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These anodes are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Substance resulting from metallurgic processing of primary sources (copper matte obtained from copper ore/concentrate) and/or secondary sources (copper scrap and/or black copper) and including recycled intermediates (i.e. spent anodes and removal cathodes). Composed primarily of copper metal and copper oxides (> 80%) and containing other residual metals and their compounds. The raw material for a copper anode comes from one of two places; the copper is either refined or scrap material. Refined copper comes in the form of a copper cathode, named so because copper is electrolytically refined (plated out of solution). In this process, blister copper (approximately 95% copper) is dissolved anodically and high purity copper metal is plated slowly on a cathode with the impurities falling to the bottom of the plating tank as sludge. The impurities in the sludge include iron, sulfur, tellurium, selenium, gold, silver, zinc, arsenic, and others. The resulting cathode is 99.95% pure copper and can now be melted to form anodes. Scrap copper is generated daily around the world from such sources as utility wires, telephone wires, transformers, water tubes, buss bars, and other sources. This material is usually grouped and sorted by a scrap dealer. The disadvantage of scrap metal is its potential for contamination. All of the previously mentioned sources contain steel, tin, silver, and/or lead. The metals can also be mixed when sorting, and copper alloys can be mistaken for pure copper. Some metallic impurities in copper anodes can be dissolved and plated. These dissolved impurities will increase in concentration over time, resulting in a bath saturated with metallic contaminants. Plated impurities can cause stress and roughness on the plated part, which, in turn, cause difficulties in plating and process control, higher additive consumption (brightener) and scrap parts. These impurities usually go undetected until production problems appear because they are not normally examined in routine analysis.Grain Structure. The grain structure is the most important characteristic of copper anodes; this structure is completely determined by the process used to manufacture the anodes, which we will now explore. Casting of copper anodes is the simplest and least costly method; however, cast copper anodes do not exhibit the fine, uniform grain structures necessary for superior plating. Higher casting speeds will increase production and reduce costs, but will also result in larger grain size, and, therefore, inferior grain structure. Treatment is required subsequent to casting in order to produce copper anodes with a fine grain structure. This usually involves hot rolling, hot extruding, or hot forging. When the copper is formed under high temperature and pressure the grain structure is reformed and becomes fine and uniform. It should be noted that copper used for a variety of functions, other than anodes, require fine grain structures (wire, buss bars, copper foil and sheets). Overall, copper anodes containing higher impurities and without a fine grain structure will dissolve unevenly, have a higher sludge yield, result in lost copper dropping into solution, and have the potential to increase the roughness of plated parts. The results below show the sludge weight left in solution after 30 minutes of plating at 15ASF with four different types of copper anode balls. Filtered Solution (Weight of Sludge). Phosphorus content. Phosphorus content for acid copper plating is ideally maintained between 0.040 and 0.065%. Metallurgically, impurities are located at grain boundaries. Therefore, phosphorus (required for acid copper plating) is most evenly distributed in fine grain anodes. Typically, a black film develops as a result of the phosphorus in the anode. This film keeps fine pieces of copper from falling off of the anode as sludge and also retards corrosion of the anode. Anodes with large grain structures will develop a black film, but this film will not be adherent and quickly turn into sludge. The sludge now contains usable copper (lost metal) that can plug up anode bags and fall into solution causing roughness on plated parts.Cleanliness. Manufacturing oils, oxidation, and burrs must be removed from copper anodes. Copper oxidizes when it freezes from the molten state or when heated for rolling, forging, or extruding. This oxidation must be removed either by mechanical abrasion or acid pickling followed by neutralization. Mechanical methods are preferred because there is no residue. In the manufacture of bar anodes sawing, drilling, and tapping oils are used to lubricate the tooling. The oils are applied to the copper as well as the tooling. Proper washing and rinsing removes these residual oils or coolants (organic compounds) which would contaminate the plating bath. Anode nuggets are typically made by cutting copper rod into various lengths. This shearing process creates burrs and sharp edges that can drop into tanks or cause the nuggets to bridge or nest in titanium mesh baskets, causing voids of anode, uneven plating distribution, and anode polarization. In addition, burrs and sharp edges are hazards to the operators handling the material. Anodes should be inspected carefully to determine that the material has come from the manufacturer ready for use with no pretreatment necessary. Anode balls are formed by either cold forging (heading) or hot roll forging copper rod of various thickness. Copper wire being headed should preferably already have a fine grain structure. Normally copper balls that are hot roll forged will have a post-treatment procedure to ensure they will have a fine grain structure.

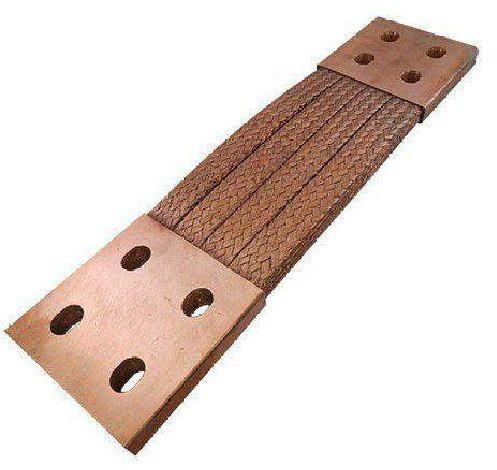

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Copper |

| Conductor Material | Electrolytic Copper Cu-ETP (grade C101), Oxygen Free Copper |

| Surface Finishing | Tin Plated |

| Color | Copper |

| Application | Earthing Straps, Electrical Components |

| Thickness | Specified Width And Thickness |

| Finish | Wide Range Of Finishes |

| Plating | Tin Plated |

| Flexibility | Super Flexible |

| Product Code | 85389000 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 10-15 DAYS |

| Packaging Details | IN CORRUGATED BOX PACKING, WOODEN BOX IF REQUIRED, |

Our super flexible flat copper braids (copper tapes) are made to order from 0.05 mm diameter wire are braided into a tube followed by a rolling process to flatten them to the specified width and thickness. They are used as earthing straps and in numerous electrical components. These super flexible flat copper braids can be made in electrolytic copper Cu-ETP (grade C101) or oxygen free copper and in a wide range of finishes. Tin plated super flexible copper braid is made from 0.071 mm dia wire. The braid can be folded back on itself, as shown in the pacture. All our copper braids are RoHS compliant.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Heating Systems,Refrigerant Lines In HVAC Systems |

| Type | Tubes |

| Material | Copper |

| Resistance | Corrosion Resistant |

| Strength | Superior Mechanical Strength |

| Installation | Easy Installation |

| Cost-effectiveness | Improved Cost-effectiveness |

| Welding | Well Suited To Welding And Brazing |

| Joining Methods | Flare Connection, Compression Connection, Pressed Connection, Solder |

| Corrosion Resistance | High Level Of Corrosion Resistance |

| Product Code | 74111000 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 20-25 DAYS |

Product Description:The precision manufactured Copper Tubes offered by us find usage in a variety of applications. With the minimum copper content of 99.9% as per IS-191, these copper tubes are also resistant to corrosion and feature superior mechanical strength.These tubes have the superior mechanical strength and provide for low-pressure loss. These are easy in installation, thus helping in achieving improved cost-effectiveness as compared with other metals. The deoxidized copper is also well suited to welding and brazing.Copper tubing is most often used for heating systems, and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly. Generally, copper tubes are soldered directly into copper or brass fittings, although compression, crimp, or flare fittings are also used. Formerly, concerns with copper supply tubes included the lead used in the solder at joints (50% tin and 50% lead). Some studies have shown significant leaching of the lead into the potable water stream, particularly after long periods of low usage, followed by peak demand periods. In hard water applications, shortly after installation, the interior of the pipes will be coated with the deposited minerals that had been dissolved in the water, and therefore the vast majority of exposed lead is prevented from entering the potable water. Building codes throughout the U.S. require the use of virtually "lead-free" (<0.2% lead) solder or filler metals in plumbing fittings and appliances.We are manufacturer & supplier of type M and DWV copper pipe, Rigid copper pipe & Copper Round Pipe. We are stocking distributor of Copper Pipe in various types & shapes. Check our latest price list of Copper Welded Pipe & SCH40 Copper Pipe. We have wide stock of Copper Alloy Pipe, type b copper pipe & a/c copper pipe. Copper Seamless Pipe is preferred by some because it is durable and flexible making it easy to install. Copper Pipe meets ASTM B88 standards and also provide an environment that makes it very difficult for bacteria to grow which is an important health consideration and is widely used in the transporation of water in both commercial and domestic installations. Soft (or ductile) copper pipe can be bent easily to travel around obstacles in the path of the tubing while Rigid copper pipe is a popular choice for water lines. Jans Copper P Ltd in renowned Manufacturer of type d copper pipe in India. We manufacture of all types on copper pipe for water & type g copper pipe. We have supplied type h copper pipe to Gasco, type i copper pipe to Saudi Aramco, j pole copper pipe to Oman, k copper pipe to KNPC, type o copper pipe to Qatar Gas, u shaped copper pipe to Dubai, copper pipe u bend to leading oil & gas company in Iraq, 5 mm copper pipe to South Africa, 5 inch copper pipe to North America, 5/16 copper pipe to United Kingdom and 5/8 copper pipe to UAE. We have more than 12 years of experience in supplying seamless copper pipe & all sizes of copper pipes. Our highly experienced technicians help you to buy right copper piping material. Jans Copper P Ltd offers all Copper Straight Pipes for the Oil & Gas and Refinery Industry in the form of Copper Round Pipe, Copper Hexagonal Pipe, Copper Square Pipe and Copper Hollow Pipe. Copper Thin Wall Pipe typically finds application including Marine, Aerospace industries, Chemical processing, Nuclear reactors, Pollution control equipment etc.

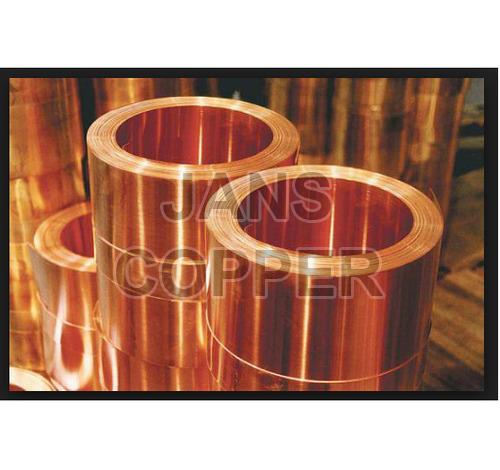

| Business Type | Manufacturer, Exporter, Supplier |

| Ultimate Strength (≥ MPa) | As Per Requirement |

| Brand Name | Jans Copper |

| Country of Origin | India |

| Material | Copper, Aluminum, Stainless Steel, Nickel, Acetal, Polyethylene |

| Thickness | 2-10 Mils, Greater Than 1mm Up To 8mm |

| Packaging Type | Coils, Sheets |

| Feature | High Thermal And Electrical Conductivity, Malleable, Ductile |

| Texture | Smooth |

| Application | Current Collectors, Stencils, Roofing, Structural Engineering, EMI/RFI Shielding, Circuit Boards, Heat Exchanging |

| Grade | Electro Tough Pitch (110 Alloy), Oxygen Free (102 Alloy) |

| Internal Diameter | Up To 20 Inches |

Copper and aluminum foils are used as current collectors at the anode and cathode side. Both materials are highly stable with melting points >600°C (Table 7B.4). Accordingly, the current collectors do not contribute to the initiation of the thermal runaway of a cell, but at higher temperatures (>700°C) a thermite-style reaction between the Al and metal oxide of the cathode is in discussion. In the case of the copper foil, corrosion can lead to an internal short circuit caused by growing copper dendrites on the anode during deep discharge. Most stencils are fabricated from stainless steel, nickel, or copper foil 2–10-mils thick. Apertures are formed in the foil by one of three processes: chemical etching, laser cutting, or electroforming. Chemical etching, although the least costly of the three methods, provides the coarsest features. In chemical etching the apertures, the metal foil is coated on both sides with a photosensitive coating, exposed to UV light through a mask that has the desired aperture pattern, and developed. The part is then immersed or sprayed with a chemical etchant that removes metal only in the unprotected areas, after which the photocured coating is removed. With the trend toward finer pitch devices (less than 20-mil pitch), both laser-cut and electroformed stencils must be used. Laser-cut stencils can be produced directly from Gerber data by computer numerically controlled laser cutting. Aperture dimension tolerances of ±5 μm are reported. Chemically etched and laser-cut stencils are formed by subtractive processes. On the other hand, electroformed stencils are produced by an additive process in which a metal such as nickel is electroplated onto a mandrel that has a negative photoresist image of the aperture pattern. The electrodeposited nickel containing the apertures is then removed from the mandrel and used as the stencil. Because of their high precision patterns, electroformed stencils are used for ultra-fine pitch applications. In recent years, there has been increased interest in stencils produced from plastics such as acetal and polyethylene. The prime benefit in using plastic stencils is the thicknesses that can be used (greater than 1 mm up to 8 mm). By drilling apertures of various sizes, adhesive deposits of different heights ranging from 0.2 to 2 mm were printed from a single screen thickness in one pass. Figure 4.4 shows a typical range of dot heights that were produced from a 1-mm-thick plastic stencil having aperture sizes from 0.6 to 2 mm. By carefully controlling the aperture size, it is possible to produce heights for every component type with a single squeegee stroke across a printed-circuit board Copper is an influential metal for both industrial and consumer applications. Our copper foil inventory consists of Electro Tough Pitch (110 alloy) and Oxygen Free (102 alloy). We also have copper foil sheeting and other copper foil sheet products that are Hot Tin Dipped to enhance solderability. Copper is a versatile metal used in a variety of industries. Major characteristics include being a malleable and ductile metal with a very high thermal and electrical conductivity. Copper foil is available in Alloys 110 and 102. Upon request, other alloys are also available. Its many applications include: roofing, structural engineering, EMI/RFI shielding, circuit boards, and heat exchanging. These copper coils can be supplied on fiber, aluminum, steel, and plastic cores with inner diameters up to 20”. Available tempers include annealed, full hard, and as-rolled.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Electroplating, Rotogravure, Electroforming, Printed Circuitry, Ground Rod |

| Brand Name | Jans Copper |

| Size | Oval - 80mm X 30mm, 25mm, 38mm, 50mm |

| Material | Copper |

| Type | Phosphorous Copper Balls (Cu-DHP) |

| Purity | 99.9% Copper |

| Country of Origin | India |

| Condition | Suitable Metallurgical Condition |

| Feature | Free From Impurities, Safeguard From Contamination |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 1-2 DAYS |

Product Description:Phosphorous Copper Balls (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These balls are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications. Jans Copper Pvt Ltd is one of the leading Copper Ballss, Copper Balls & Copper Nuggets manufacturer and supplier in India. Jans Copper Pvt Ltd's Copper Ballss, Copper Balls & Copper Nuggets are manufactured in accordance with the defined international standards. The raw material that is used to manufacture SIMCO copper products are LME grade ‘A’ cathodes of purity greater than 99.99% copper resulting in higher conductivity, crack free extrusion, excellent finish and longer life. Available Sizes As per customer’s requirement Available Grades ETP, OFC, Phosphorised Copper Plating / Coating Bare Additional Specifications / Details Available in all forms i.e. Oval, Slabs, Balls, Rods, Nuggets, etc. Applications / Uses Printed circuit boards, Rotogravure, Electroforming, etc. Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Product Description:Phosphorous Copper Balls (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These ballss are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Substance resulting from metallurgic processing of primary sources (copper matte obtained from copper ore/concentrate) and/or secondary sources (copper scrap and/or black copper) and including recycled intermediates (i.e. spent balls and removal cathodes). Composed primarily of copper metal and copper oxides (> 80%) and containing other residual metals and their compounds. The raw material for a copper balls comes from one of two places; the copper is either refined or scrap material. Refined copper comes in the form of a copper cathode, named so because copper is electrolytically refined (plated out of solution). In this process, blister copper (approximately 95% copper) is dissolved anodically and high purity copper metal is plated slowly on a cathode with the impurities falling to the bottom of the plating tank as sludge. The impurities in the sludge include iron, sulfur, tellurium, selenium, gold, silver, zinc, arsenic, and others. The resulting cathode is 99.95% pure copper and can now be melted to form ballss. Scrap copper is generated daily around the world from such sources as utility wires, telephone wires, transformers, water tubes, buss bars, and other sources. This material is usually grouped and sorted by a scrap dealer. The disadvantage of scrap metal is its potential for contamination. All of the previously mentioned sources contain steel, tin, silver, and/or lead. The metals can also be mixed when sorting, and copper alloys can be mistaken for pure copper. Some metallic impurities in copper ballss can be dissolved and plated. These dissolved impurities will increase in concentration over time, resulting in a bath saturated with metallic contaminants. Plated impurities can cause stress and roughness on the plated part, which, in turn, cause difficulties in plating and process control, higher additive consumption (brightener) and scrap parts. These impurities usually go undetected until production problems appear because they are not normally examined in routine analysis. Grain Structure. The grain structure is the most important characteristic of copper ballss; this structure is completely determined by the process used to manufacture the ballss, which we will now explore. Casting of copper ballss is the simplest and least costly method; however, cast copper ballss do not exhibit the fine, uniform grain structures necessary for superior plating. Higher casting speeds will increase production and reduce costs, but will also result in larger grain size, and, therefore, inferior grain structure. Treatment is required subsequent to casting in order to produce copper ballss with a fine grain structure. This usually involves hot rolling, hot extruding, or hot forging. When the copper is formed under high temperature and pressure the grain structure is reformed and becomes fine and uniform. It should be noted that copper used for a variety of functions, other than ballss, require fine grain structures (wire, buss bars, copper foil and sheets). Overall, copper ballss containing higher impurities and without a fine grain structure will dissolve unevenly, have a higher sludge yield, result in lost copper dropping into solution, and have the potential to increase the roughness of plated parts. The results below show the sludge weight left in solution after 30 minutes of plating at 15ASF with four different types of copper balls balls. Filtered Solution (Weight of Sludge). Phosphorus content. Phosphorus content for acid copper plating is ideally maintained between 0.040 and 0.065%. Metallurgically, impurities are located at grain boundaries. Therefore, phosphorus (required for acid copper plating) is most evenly distributed in fine grain ballss. Typically, a black film develops as a result of the phosphorus in the balls. This film keeps fine pieces of copper from falling off of the balls as sludge and also retards corrosion of the balls. Ballss with large grain structures will develop a black film, but this film will not be adherent and quickly turn into sludge. The sludge now contains usable copper (lost metal) that can plug up balls bags and fall into solution causing roughness on plated parts. Cleanliness. Manufacturing oils, oxidation, and burrs must be removed from copper ballss. Copper oxidizes when it freezes from the molten state or when heated for rolling, forging, or extruding. This oxidation must be removed either by mechanical abrasion or acid pickling followed by neutralization. Mechanical methods are preferred because there is no residue. In the manufacture of bar ballss sawing, drilling, and tapping oils are used to lubricate the tooling. The oils are applied to the copper as well as the tooling. Proper washing and rinsing removes these residual oils or coolants (organic compounds) which would contaminate the plating bath. Balls nuggets are typically made by cutting copper rod into various lengths. This shearing process creates burrs and sharp edges that can drop into tanks or cause the nuggets to bridge or nest in titanium mesh baskets, causing voids of balls, uneven plating distribution, and balls polarization. In addition, burrs and sharp edges are hazards to the operators handling the material. Ballss should be inspected carefully to determine that the material has come from the manufacturer ready for use with no pretreatment necessary. Copper balls are formed by either cold forging (heading) or hot roll forging copper rod of various thickness. Copper wire being headed should preferably already have a fine grain structure. Normally copper balls that are hot roll forged will have a post-treatment procedure to ensure they will have a fine grain structure. Overall, there are several characteristics that determine the quality of the copper anodes manufacturing process. These include: purity of copper, fine grain structure, uniform phosphorus content and distribution, and properly cleaned and anodes packaged and ready for use. Therefore, the quality of copper anodes should be very important to electroplaters because properly manufactured anodes will: extend bath life; have less metallic contamination; produce parts without roughness; have less sludge; and require less maintenance.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jans Copper |

| Application | Electrical Conductivity,EMI Shielding, Slug Repellent, Guitar Shielding |

| Material | Copper |

| Thickness | 0.1mm, 0.2mm, 0.3mm |

| Packaging Type | Roll |

| Feature | Conductive, Adhesive |

| Design | Plain |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jans Copper |

| Country of Origin | India |

| Material | Copper |

| Thickness | 0.1mm - 3mm |

| Packaging Type | Rolls, Spools |

| Width | 10mm - 100mm |

| Adhesive | Acrylic Adhesive |

| Sheet Thickness | 0.1mm - 3mm |

| Electrical Resistivity Of Copper | 1.68 X 10^-8 Ohm.m |

| Copper Melting Point | 1084.62°C |

| Design | Plain |

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Size | 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm |

| Feature | Crack Proof, Excellent Quality, Fine Finishing, High Strength |

| Brand Name | Jans Copper |

| Type | Copper Profiles |

| Material | Copper |

Application Areas:

- Power generation-Hydro-generators

- Turbo-generators

- Wind-generators

- Nuclear-generators

- Electrical appliances

- Heat Sinks

- CPU Coolers

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Brand Name | Jams Copper |

| Width | 3 Mm To 160 Mm |

| Thickness | 0.5 Mm To 10 Mm |

| Material | Copper |

| Power Source | Electric, Solar |

| Grade | JIS, BS EN, DIN, ASTM, IS |

| Area of Applications | Electrical Conductors, Switch Terminals, Hardware used in Electrical Circuits |

| Product Code | 74091900 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 15-20 DAYS |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jans Copper Pvt Ltd |

| Country of Origin | India |

| Material | Copper |

| Length | Customizable |

| Grade | Electrolytic Grade Copper |

| Packaging Type | Standard Packaging |

| Feature | Rugged Design, High Strength, Fine Finish |

| Technics | Braided |

| Conductor Material | Copper |

| Width | Customizable |

| Application | Various Places, Electrical And Electronic Applications,Bonding Metal Gates, Earth Bonding, Flexible Electrical Connections |

This Flexible Copper Braid is used for bonding metal gates, etc. This is suitable for Earth Bonding It can be supplied as Standard Drilled & Precut Bonds. Braids made of many copper wires are also sometimes used for flexible electrical connections between large components The numerous smaller wires comprising the braid are much more resistant to breaking under repeated motion and vibration than is a cable of larger wires In electrical and electronic cables, braid is a tubular sheath made of braided strands of metal placed around a central cable for shielding against electromagnetic interference The braid is grounded while the central conductor or conductors carry the signal We are exporter and manufacuture of copper flexible braided strip as per customer requirement and size. our copper material has 99.9% purity, comes in Electrolytic grade copper. Features: Rugged design High strength Fine finish The offered braided copper strips are widely suited in a various places due to its quality & durability. These Braided copper strips are made accessible in several stipulations for our customers to choose from. Along with that, these braided copper strips are examined on several stages by our highly competent professionals assuring its excellence to users'' end. Patrons can take these braided copper strips from us at pocket friendly rates. Features: Dimensional accuracy Rust resistance Precise designing