Bhuleshwar, Mumbai, Maharashtra

- GST NO. : 27AACPJ1600P1ZT

View Mobile Number

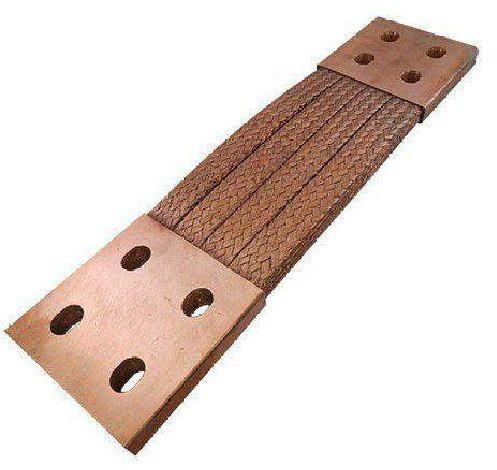

Flexible Copper Products

Leading Manufacturers, Exporters and Wholesaler of Braided Copper Flexibles, Braided Wire, Laminated Copper Connector and Flexible Copper Connectors from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Copper |

| Conductor Material | Electrolytic Copper Cu-ETP (grade C101), Oxygen Free Copper |

| Surface Finishing | Tin Plated |

| Color | Copper |

| Application | Earthing Straps, Electrical Components |

| Thickness | Specified Width And Thickness |

| Finish | Wide Range Of Finishes |

| Plating | Tin Plated |

| Flexibility | Super Flexible |

| Product Code | 85389000 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 10-15 DAYS |

| Packaging Details | IN CORRUGATED BOX PACKING, WOODEN BOX IF REQUIRED, |

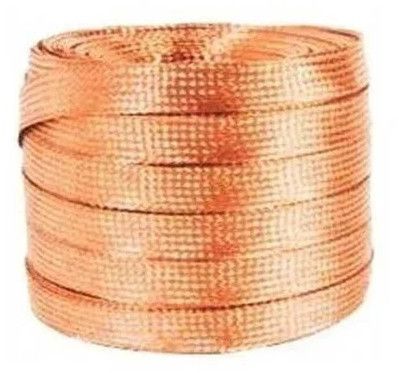

Our super flexible flat copper braids (copper tapes) are made to order from 0.05 mm diameter wire are braided into a tube followed by a rolling process to flatten them to the specified width and thickness. They are used as earthing straps and in numerous electrical components. These super flexible flat copper braids can be made in electrolytic copper Cu-ETP (grade C101) or oxygen free copper and in a wide range of finishes. Tin plated super flexible copper braid is made from 0.071 mm dia wire. The braid can be folded back on itself, as shown in the pacture. All our copper braids are RoHS compliant.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Jams Copper |

| Material | Copper |

| Thickness | 1mm - 60mm |

| Width | 5mm - 350mm |

| Edge Type | Radius Corner Edge, Square Edge, Full Radius Edge |

| Application | Medical, Automotive Industries, Power Distribution, Telecommunication |

| Edge Length | Up To 6400mm (21`) |

| Uses | Bus Bars, Transformer Connectors, Power Transmission Equipment, Control Panels |

| Product Code | 74130000 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 10-15 DAYS |

| Packaging Details | HESSIAN CLOTH BUNDLE PACKING, WOODEN BOX, REEL, ETC |

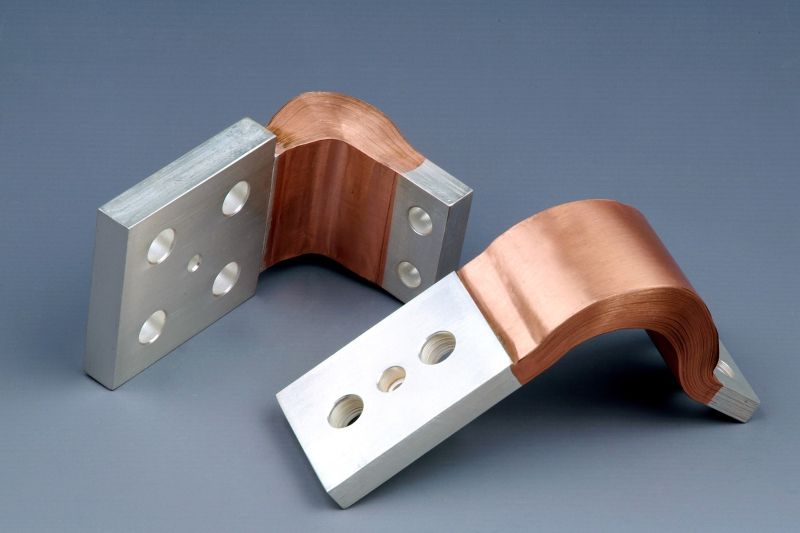

Thickness 1mm To 60mm Standard IS Brand Name Jams Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram insulated flexible copper bars are mainly utilised for providing the power connections between busbars and the disconnection devices within an electrical panel. The insulated layered copper allows the flexible copper bar to be easily formed to provide a customised solution. Advantages Easy to install • Compact version. • High level of flexibility enabling easy manipulation of the busbar. • Reduced installation time with the elimination of terminal lugs and their crimping. Increased safety by the elimination of crimped connections • Better behaviour under short-circuit conditions. • Decreased number of heating points. • More reliable connections.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Feature | Flexible, Laminated, High Conductivity |

| Grade | Electrolytic Grade |

| Certification | ASTM B33, ASTM-D-149 |

| Application | Power Plants, Switchgear Industries, Cathodic Protection, Bus Ducts, Transformer, V.C.B., Resistance Welding Engineering, Electric Locomotives, Galvano Engineering, Furnace |

| Color | Copper |

| Finishing | Press Welding |

| Size | Customized |

| Product Code | 85381010 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 10-15 DAYS |

| Packaging Details | IN CORRUGATED BOX PACKING AND WOODEN BOX IF NEEDED. |

The complete range of Flexible Copper Products includes Copper Flexible Laminated, Copper Flexible Braid, Copper Flexible Link and Copper Flexible Bus Bars. Here, our expertise lies in matching up with the complete demands of the customers including in varied usage environment. Further, these flexible copper products also feature superior electrical & mechanical properties at high temperatures.These are also made available in all sizes matching up to the demands of different cross section areas. Here, we can also offer these in other customized finish specifications as per the specific requirements of the customers. Product Details: Usage/Application Power Plants, switchgear industries Size As per requirement Standard & Material ASTM B33, ASTM-D-149 Area of Applications Switchgear industries,Power plants,Cathodic Protection,Bus Ducts,Transformer,V.C.B. Brand Jans Copper Pack Size As per customer requirement Product Description: Laminated and Flexible Copper are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material.The process assures minimum resistance and helps in increasing product’s service life as well as bringing a reduction in downtime. Further, these also come with superior mechanical electrical properties at high temperatures. General Properties: Standard Material - ASTM B33, ASTM-D-149 Application Areas: Switchgear industries Power plants Cathodic Protection Bus Ducts Transformer V.C.B. Resistance welding engineering Electric Locomotives Galvano Engineering Furnace RequestCallback Additional Information: Delivery Time: As per requirement

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Copper, Stainless Steel |

| Feature | High Conductivity, Earth Bonding, Drilled & Pre-Cut Bonds |

| Finishing | Standard |

| Standard | Bs-4109, C101 |

| Area Of Applications | Switch Gear, Power Plants, Cathodic Protection, Bus Ducts, Transformer, V.C.B., Resistance Welding Engineering, Electric Locomotives, Galvano Engineering, Furnace |

| Pack Size | Customer Specific |

| Conductor Type | Copper |

Application Areas: Switch Gear industries Power plants Cathodic Protection Bus Ducts Transformer V.C.B. Resistance welding engineering Electric Locomotives Galvano Engineering Furnace Copper, which has chemical symbol as Cu and atomic weight 29, is the most widely used metal in electrical and Manufacturing industry. Electronics component such as integrated circuits, electro-magnets and printed circuit boards are created using copper and products related to copper. Electrical Connectors use the mechanical assembly to connect or join electrical circuits to be used as an interface. Due to the nature of operation, an electrical connector needs to be manufactured using precise configuration and calculations. Copper wires are the most widely used metals for creating electrical conductors. Copper, has the maximum electrical conductivity and thermal conductivity which makes them as an ideal material for Manufacturing electrical connectors. Braided flexible connectors and jumpers are important components of electronics industry. These are manufactured using copper as well as stainless steel bellows, which are sometimes covered to provide additional strength and support. The main purpose of braided flexible connectors is to deliver maximum power output, even during peak performance. In those sectors, where the demand of power is much, and the wires experience considerable load, then braided flexible connectors can be an efficient solution for optimal power output. Some of the advantages of using braided flexible connectors are: · Control and absorb the vibrations · Manage the natural expansion and compression of wires during power transmission · Provide minimum resistance for seamless productivity Braids made of many copper wires are also sometimes used for flexible electrical connections between large components. The numerous smaller wires comprising the braid are much more resistant to breaking under repeated motion and vibration than is a cable of larger wires. In electrical and electronic cables, braid is a tubular sheath made of braided strands of metal placed around a central cable for shielding against electromagnetic interference. The braid is grounded while the central conductor or conductors carry the signal. - High conductivity copper - Wire to Bs - 4109 - C101 - Suitable for Earth Bonding/ also supplied as Standard Drilled & Pre-Cut Bonds. - Customer specific sizes & types of braid can be manufactured on order. Even though many of our products are standard items, we also make special tailor made products made exactly to the requirements of our customers. Electrical engineers in power generation are aware of this simple fact: Vibration is an enemy of electrical connectivity.