Bhuleshwar, Mumbai, Maharashtra

- GST NO. : 27AACPJ1600P1ZT

View Mobile Number

Copper Bars

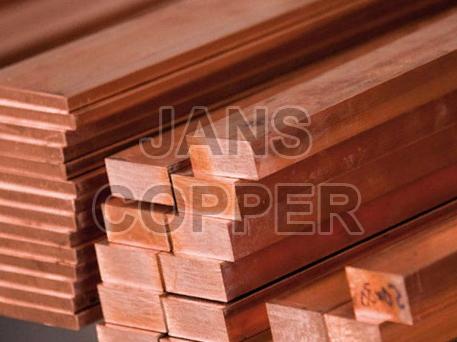

Leading Manufacturers, Exporters and Wholesaler of Copper Busbar, Copper Hex Bars, Copper Square Bars, Copper Braided Busbar and Laminated Copper Busbars from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Copper |

| Application | Medical, Automotive Industries, Power Distribution, Telecommunication,Bus Bars, Transformer Connectors, Power Transmission Equipment, Control Panels |

| Thickness | 1mm To 60mm |

| Width | 5mm To 350mm |

| Edge Type | Radius Corner Edge, Square Edge, Full Radius Edge |

| Edge Length | Up To 6400mm (21`) |

| Standard Overall Cutting Tolerance | 100mm |

Thickness 1mm To 60mm Standard IS Brand Name Jans Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram

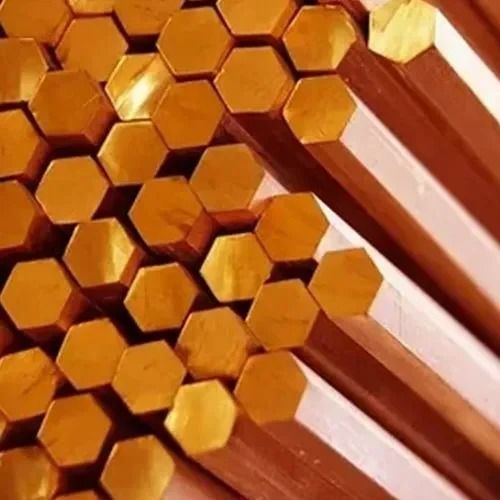

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Finishing | Polish |

| Material | Copper |

| Thickness | 4 Mm To 75mm |

| Country of Origin | India |

| Size | 25 |

| Weight | Weight per feet in kg |

| Standard | -BS, IS, AMS, DIN & All International Standards |

| Technique | Drawn |

| Product Code | 74071020 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | 10-15 DAYS |

Application Areas:

- Bus Bars

- Transformer Connectors

- Earthing Protection in L.T. and H.T. Electrical Panels

- Power Transmission equipment

- Control Panels

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Copper |

| Shape | Square |

| Thickness | 1mm To 60mm |

| Application | Bus Bars,Transformer Connectors,Earthing Protection,Power Transmission Equipment,Control Panels,Medical Industries,Automotive Industries,Power Distribution,Telecommunication |

| Size | Width: 5mm To 350mm, Edge Length: Up To 6400mm |

Application Areas: Bus Bars Transformer Connectors Earthing Protection in L.T. and H.T. Electrical Panels Power Transmission equipment Control Panels Thickness 1mm To 60mm Standard IS Brand Name Jans Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram

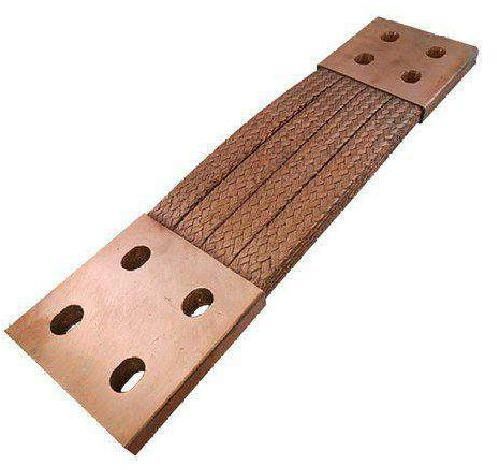

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Copper |

| Brand Name | Jans Copper Pvt Ltd,Jans Copper |

| Country of Origin | 110V,220V,380V,440V |

| Type | Braided Busbar |

| Application | Switchgear, Automobiles Industries, Hard Engineering Machines, Busbar Systems |

| Surface Finishing | Tin Plated, Silver Plated |

We supply high power copper braid connectors for busbar to transformers, busbars to busducts, busbars to gen sets, busbars to UPS systems, busbars to generators, busbars to isolators, busbars to switches, busbars to circuit breakers, busbars to fuses, busbars to ACBs, busbars to MCCBs and any other electrical connections within a power transmission system. aided Copper Flexible Connectors provide a low resistance flex connector between two rigid bus bar sections that have dynamic motion. Braided Copper Flexible Connectors are widely used in electrical distribution, switchgear and automobile industries because of excellent flexibility. Copper Braided Connectors have characteristics of expansion and contraction. Jans Copper P Ltd is an established Manufacturer, Exporter & Supplier of Copper Braided Flexible Connectors, Copper Braided Flexible Wire, Copper Braided Strip, Braided Copper Flexible Busbar, Copper Braided Rope with bare, tin and silver plating options depending upon customer’s needs. Copper braided strips, ropes are made from electrolytic grade copper wire of diameter depending upon customer’s requirements. These strips and ropes are then pressed with copper connectors. We manufacture copper braided flexible connectors & braided copper flexible busbar and supply them all over the globe. With our years of experience and expertise, our highly skilled personnel, and precision engineering techniques we are able to cater to various industries that require these products in bulk and on a regular basis. Copper Braided Flexible Connectors Plating Options: Tin Plated Copper Braided Flexible Connectors Silver Plated Copper Braided Flexible Connectors Features Of Braided Copper Flexible Connectors: High durability Superior conductivity Heat resistance High strength Excellent finish Longer life Applications Of Copper Braided Flexible Connectors: Switchgear Automobiles Industries Hard engineering machines Busbar Systems The raw material that is used to manufacture our copper products is LME grade ‘A’ cathodes of purity greater than 99.99%. Jans Copper P Ltd also provides plating solutions on Copper Braided Flexible Connectors, Braided Copper Flexible Busbar, Copper Braided Flexible Wire, Copper Braided Strip to give the perfect contact. Braided Copper Flexible Connectors are individually designed and manufactured in accordance with the customer’s requirement

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Brand Name | Jans Copper |

| Packaging Type | Copper,Metallic |

| Surface Finishing | Polished,Power Coated |

| Standard | ASTM D4014,CE EN 1337-3,IEC-60137:2008,ASTM |

| Depth | 0-10mm,10-20mm,20-30mm,30-40mm,40-50mm,50-60mm,60-70mm,70-80mm |

| Automation Grade | Automatic,Hydraulic,Riveting |

| Length | Up to 1000mm |

| Edge Type | Radius Corner Edge, Full Radius Edge, Square Edge |

Product Description: Copper Laminated Busbars comprise flexible laminated copper connections that are produced using highly conductive electrolytic grade copper foil & sheets. These laminated Busbars undergo press welding where individual copper strips are fused through applying direct current as well as pressure, which results in ensuring minimum resistance as well as in enhancing the product life as well as in the reduction of downtime. Further, these also feature superior mechanical & electrical properties at higher temperatures. These also feature higher power density as well as better electromagnetic compatibility (EMC). Laminated Busbar is applied to implementing the connection of power devices in electric and electronic products. Through the parallel and laminated structure of the positive and negative electrodes, the inductance distributed among the circuit is reduced, which helps reduce the peak reverse voltage of both ends of the power elements and lower the requirements of voltage protection and circuit absorbing. This structure is aimed at improving the reliability and stability of power devices and the circuit integration for easier repair and maintenance. Laminated Busbar could be customized or specified according to your design or drawings. It also could be designed and developed according to your application and requirements. We are making various types of Profile busbars . These busbars are produced on Fibre optic laser machine and water jet cutting machine to get the required profile and accuracy .